|

To contact us: |

|

8425 State St P.O Box 304 Gasport, NY 14067

Phone: 716.772.2651 Fax: 716.772.2555

|

|

Mounted Pump/Motor Units and Turnkey Systems |

|

Base

Mounted

Pump

Units |

|

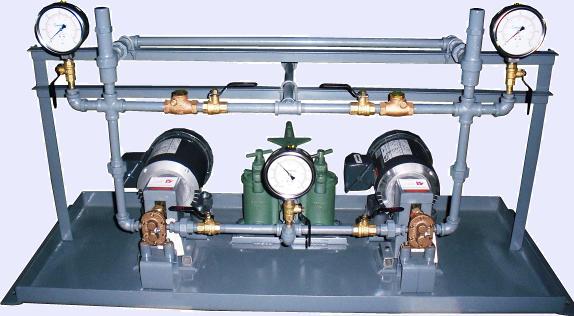

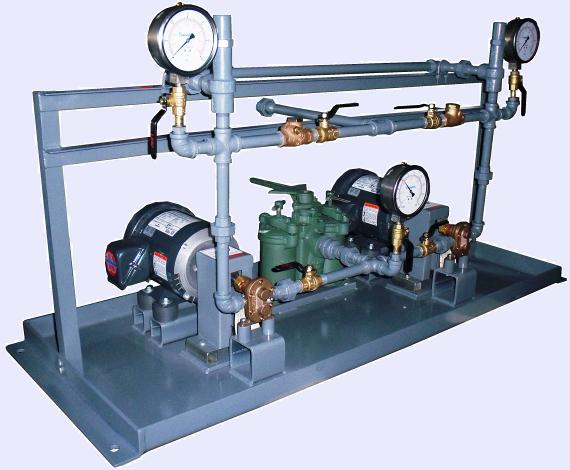

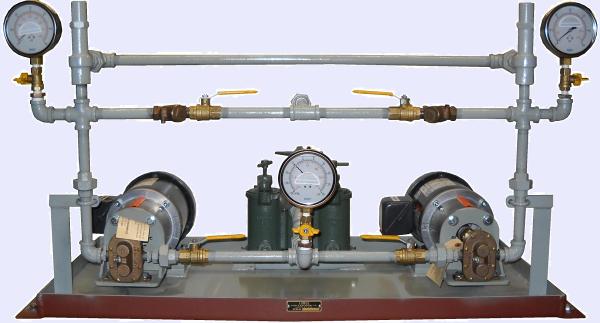

Duplex Fuel or Lube Oil System |

|

Lobee Pump & Machinery Co. Industrial Pumps and Accessories |

|

Since 1899...Noted for Highest Quality Pumps and Equipment |

|

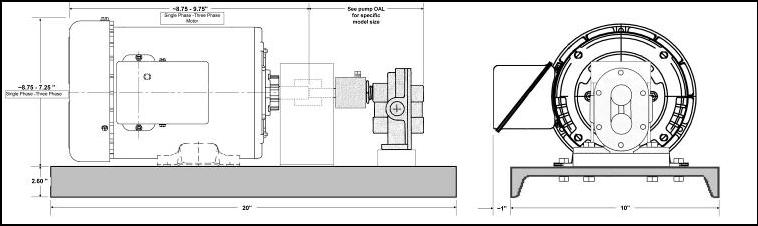

C-Face

Direct

Mounted

Pump

Units |

|

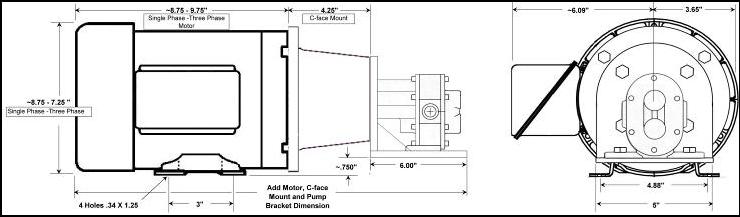

-Detail Direct Mount Envelope Dimensions |

|

Process Pumps for Industry |

|

Standard C-Face Direct Mounted Dimensional Layout |

|

Standard Base Mounted Dimensional Layout |

|

Standard Features and Benefits

· Base or Direct Mounted Units · Up to 5 HP, Motors are 56 to 215 Frame, Single and Three Phase, ODP, TEFC(NV), Wash-Down, Explosion Proof, available in Standard, High and Premium Efficient · Flows to 30 GPM · Viscosity to 100,000 SSU · Choose from any Lobee Gear Pump - 316 and Alloy 20 Stainless Steel, Federalloy™ Bronze or Cast Iron · Port sizes from 1/8” to 1-1/2” NPT · Multiple Seal Options · 0-1800 RPM Range of Operation · Bi-Directional Shaft Rotation · Operating Temperatures to 450° F · Continuous Working Pressure up to 150 PSI · Integral in Pump or Externally Plumbed Adjustable Relief Valves · Suction Screens Available for Particulate Removal |

|

POSITIVE DISPLACEMENT PUMP UNITS - 1/3 TO 5 HP |

|

Lobee Positive Displacement Pump Units are now available in a range of sizes and configurations. Standard built to order pump units come in 1/3, 1/2, 3/4, 1, 1-1/2, 2, 3 and 5 HP ratings. Each unit is assembled to customer specification including pump type, flow and pressure rating, with or without relief valve, direct or base mounted, and coupled to ODP, TEFC(NV), Wash-Down or Explosion-Proof motor. Designed for pumping viscosities from water to molasses . Speed control options include 1200 RPM Motors , Mechanical Gear Reducers and VFD (Variable Frequency Drive). |

|

Typical Applications: · Food oils, syrups, coatings and additive transfer · Water, glycol and oil based coolant and heating systems · Laboratory chemical and solution testing · Marine fresh water systems · Caustic and corrosive fluid transfer · Liquids mixing systems · Filtration and circulation systems

|

|

Pump Shaft Sealing Systems Include: 1. Graphite or PTFE Packing 2. Buna or Viton™ Lip Seal 3. Mechanical Seals: Type 2106 Viton™, Type 1 Viton and Type 9 PTFE are Standard Options 4. Specialty Sealing and Flush Systems Available |

|

Speed Reducers for Viscous Liquids |

|

Variable Speed Motor Drives |

|

Integral Adjustable Relief Valve |

|

Stainless Steel Alloys |

|

Bronze |

|

Iron |

|

Options and Materials - All Pump Units |

|

Available .PDF files |

|

External Adjustable Relief Valve |

|

Precision relief valves available in Brass, 316 Stainless Steel, Hastelloy, Alloy 20 (Carpenter 20™) |

|

Model 10LOL, 1 1/4” Ported with 5 HP XP Motor |

|

Model 8LOL with 2.9:1 Speed Reducer and 1 HP Motor |

|

Model 2LOL, Mechanical Seal and 1/2 HP Motor |

|

Model 3LOE, Mechanical Seal and 3/4 HP Motor |

|

316 SS Model 2LOX and 1/2 HP Motor |

|

316 SS Model 2LOE and 1/2 HP Motor |

|

Bronze Model 3LOL, Mechanical Seal and 3/4 HP Motor |

|

Bronze Model 1LOL, Mechanical Seal and 1/2 HP Motor |

|

Bronze Model 6LOM and 1/2 HP Motor |

|

316 SS Model 3LOX and 1 HP XP Motor |